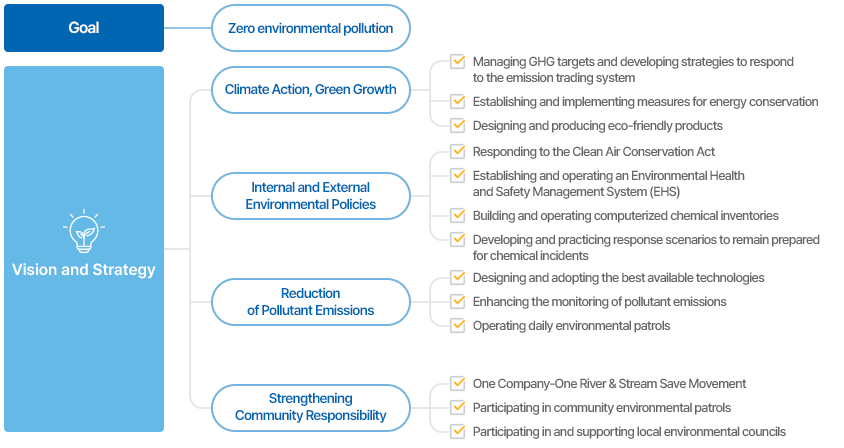

Environmental management

KPIC practices its company-wide environment management goal of "Zero environmental pollution" to open a prosperous tomorrow where humans and nature are in harmony. We operate ISO 14001, an international standard for the environmental management system, throughout the entire business process. Other activities include priority investment in pollution prevention infrastructure such as largescale wastewater treatment facility, VOC recovery facility, ULNB(Ultra Low NOx Burner), SCR (Selective Catalytic Reduction), and remote monitoring network of pollution emission status, as well as participation in voluntary agreements for energy conservation and reduction of greenhouse gas emissions, and voluntary practice of RC(Responsible Care) movement.

Environmental Management Operation System

Environmental Management Goals

Environmental compliance

KPIC strictly complies with the laws and regulations by establishing and revising internal guidelines (company rules). Areas that are not implemented as a follow-up to an internal audit are improved through corrective actions. In addition to legal regulations, we continue efforts to fulfill our eco-friendly management goals by improving environmental management through our PDCA Cycle.

<Violation of environmental laws>

| Unit | 2022 | 2023 | 2024 |

|---|---|---|---|

| No. | 0 | 1 | 0 |

※ Violation of non-monetary sanctions

<Environmental training>

| Unit | 2022 | 2023 | 2024 |

|---|---|---|---|

| Hours | 6,553 | 5,655 | 5,220 |

※ Main training: Safety training for supervisors, regular safety and health training for employees, safety training for workers who change the work contents